Small Semi-Automatic Hard and Soft Biscuit Machine

1. This mini biscuit production machine is used for making different hard and soft biscuit.

2. It's easy to operate, occupancy small and high capacity.

3. Just change the biscuit mould to change the biscuit shape and we also can design the mould for you as per your details.

4. It's suitable for the new biscuit business.

The groups of gauge rolls combine three rollers per-sheeter and combined gauge rollers in the same machine to more efficiently press the dough to the desired thickness

Rotary moulder is used in making Soft biscuit. After dough crushed by roller then go through to forming 1.Single operation system,it is also can controlled by combine with whole fine.

2.Feeding roller and crosswise milling has groove, enable the feeding sufficiently.

3.The distance between feeding roller and biscuit moulds is adjustable.

4.Rubber roller can be adjusted on either side or both sides to reduce the deviation of biscuit weight among lines.

5.The linear speed of the conveyor of biscuit mould is identical with the de-mould roller, therefore reducing biscuit deformation.

Separator For Scrap Dough

Dough sheets after going through rotary cutter and Formed into biscuit sheet, and the scrap will be conveyed to the hopper after separating.

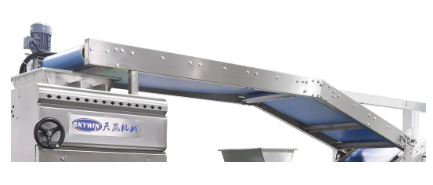

Scrap Dough Return Conveyor

Dough sheet after cutting become into biscuit shape, going through separate machine scrap will transport by conveyor to hopper for reuse.

This unit is for spraying the salt and sugar to the biscuit sheets. Making different flavor biscuit, excessive sugar will collected by the recycle device

Turnkey project, from raw materials to packaging.

* The machine performance is stable, each machine can only be matched, and the operation is simple.

* The oven is equipped with different temperature zones, which can save energy and is suitable for different types of biscuits.

* Customized services can be provided according to different requirements of customers.

* It has been upgrading and improving, and has obtained multiple patents and certificates.

FAQ

1. Who are we?

We are based in Guangdong, China, start from 2010,sell to Africa(20.00%),Mid East(19.00%),South America(15.00%),Southeast Asia(10.00%),South Asia(5.00%),North America(5.00%),Western Europe(5.00%),Eastern Asia(5.00%),Northern Europe(5.00%),Domestic Market(5.00%),Central America(4.00%),Southern Europe(2.00%). There are total about 11-50 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Biscuit Production Line/Cookies Production Line/Biscuit Sandwich Machine/Wafer Biscuit Production Line, Biscuit Packing Line

4. Why should you buy from us not from other suppliers?

Advanced Design since 1983 year High Qualtiy base on Customer requirement One-stop service for Biscuit & Cookies & Wafer Production Industry Full Auto Biscuit sandwiching and packing line Competive price In time delivery and Installation service

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union,Cash;

Language Spoken:English,Chinese