English

400mm, 600mm, 800mm,

skywin

| Availability: | |

|---|---|

| Quantity: | |

Skywin Tray Type Multi Color Wire Cutting And Depositing Cookies Making Machine

Skywin Tray Cookies machine. Tray size:400*600mm .

With Wire-cut and Depositor two functions.

Suitable for forming diferent shape cookie depends on the moulds. This machine is used for making wire cut and deposit, simple operation, occupancy small, high capacity.

It is suitable for the new business in the biscuits industry.

One or two or three colors wire cut and deposit cookie making for option.

Any mould can be customized and you just only need to change the mold to change the biscuit shape or some type .

Key Features & Benefits:

1、Precision Shaping & Flexibility:

(1)Jam/Chocolate Depositor:Inject fruit jams, chocolate, or caramel swirls during forming for multi-sensory flavor layers.Transforms basic cookies into premium, high-margin products.

(2)Dual-Mode Flexibility:Switch seamlessly between wire-cut cookies, deposited shapes, and two-tone designs with quick-change molds.

(3)Advanced Servo Motor Control: Ensures precise replication of complex cookie designs and intricate shapes.

(4)Custom Mold Capability: Molds can be tailored to your specific product requirements– ideal for branded/logoed cookies.

2、Operational & Economic Advantages:

(1)User-Friendly Design: Intuitive operation requires minimal training, ideal for new producers.

(2)Low Initial Investment: Cost-effective entry point compared to fully automated production lines.

(3)Reduced Startup Waste: Minimal trial-and-error translates to lower initial ingredient costs and quicker ROI.

(4)Space-Efficient Footprint: Compact design optimizes floor space utilization.

3、Integrated Production Solution:

(1)Perfect Oven Partner: Designed for seamless integration with rotary ovens.

(2)End Product Quality: Produces consistently baked, crispy, and flavorful cookies.

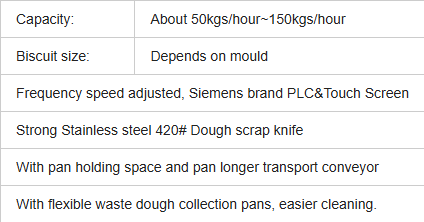

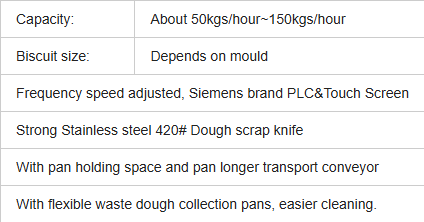

Parameter:

1.The working width can be selected as :400/600/800mm.

2.Nozzle Configuration: 400mm includes 6-7 nozzles, 600mm includes 8-10 nozzles, and 800mm includes 10-14 nozzles.

3.Capacity:50-200kg/h

4.For tray type, baked by rotary oven, tray size : 400*600mm

5.Included Tooling:

(1) Full set of wire-cut cookie molds

(1) Full set of deposit cookie molds

Custom mold design services available

JAM depositor:Added JAM depositing function

5.Drive System:

Chinese-brand servo motor & gearbox

Precision motion control for consistent shaping

FAQ

Q1:Are you manufacturer/Factory?

A1:Yes,we are 15 years factory.

Q2: How long time to delivery?

A2: After received payment 30-50 working days.

Q3: How is the payment?

A3: We accept 40% T/T deposit before production and 60% T/T balance before shipment and Western Union or L/C.

Q4:What can you buy from us?

A4:Biscuit Production Line,Cookies Production Line,Biscuit Sandwich Machine,Wafer Biscuit Production Line,Biscuit Packing Line.

Skywin Tray Type Multi Color Wire Cutting And Depositing Cookies Making Machine

Skywin Tray Cookies machine. Tray size:400*600mm .

With Wire-cut and Depositor two functions.

Suitable for forming diferent shape cookie depends on the moulds. This machine is used for making wire cut and deposit, simple operation, occupancy small, high capacity.

It is suitable for the new business in the biscuits industry.

One or two or three colors wire cut and deposit cookie making for option.

Any mould can be customized and you just only need to change the mold to change the biscuit shape or some type .

Key Features & Benefits:

1、Precision Shaping & Flexibility:

(1)Jam/Chocolate Depositor:Inject fruit jams, chocolate, or caramel swirls during forming for multi-sensory flavor layers.Transforms basic cookies into premium, high-margin products.

(2)Dual-Mode Flexibility:Switch seamlessly between wire-cut cookies, deposited shapes, and two-tone designs with quick-change molds.

(3)Advanced Servo Motor Control: Ensures precise replication of complex cookie designs and intricate shapes.

(4)Custom Mold Capability: Molds can be tailored to your specific product requirements– ideal for branded/logoed cookies.

2、Operational & Economic Advantages:

(1)User-Friendly Design: Intuitive operation requires minimal training, ideal for new producers.

(2)Low Initial Investment: Cost-effective entry point compared to fully automated production lines.

(3)Reduced Startup Waste: Minimal trial-and-error translates to lower initial ingredient costs and quicker ROI.

(4)Space-Efficient Footprint: Compact design optimizes floor space utilization.

3、Integrated Production Solution:

(1)Perfect Oven Partner: Designed for seamless integration with rotary ovens.

(2)End Product Quality: Produces consistently baked, crispy, and flavorful cookies.

Parameter:

1.The working width can be selected as :400/600/800mm.

2.Nozzle Configuration: 400mm includes 6-7 nozzles, 600mm includes 8-10 nozzles, and 800mm includes 10-14 nozzles.

3.Capacity:50-200kg/h

4.For tray type, baked by rotary oven, tray size : 400*600mm

5.Included Tooling:

(1) Full set of wire-cut cookie molds

(1) Full set of deposit cookie molds

Custom mold design services available

JAM depositor:Added JAM depositing function

5.Drive System:

Chinese-brand servo motor & gearbox

Precision motion control for consistent shaping

FAQ

Q1:Are you manufacturer/Factory?

A1:Yes,we are 15 years factory.

Q2: How long time to delivery?

A2: After received payment 30-50 working days.

Q3: How is the payment?

A3: We accept 40% T/T deposit before production and 60% T/T balance before shipment and Western Union or L/C.

Q4:What can you buy from us?

A4:Biscuit Production Line,Cookies Production Line,Biscuit Sandwich Machine,Wafer Biscuit Production Line,Biscuit Packing Line.