English

400/800/1200mm

skywin

| Availability: | |

|---|---|

| Quantity: | |

Skywin High Speed Pretzel Biscuit Making Machine Snack Production Line Bakery Equipment

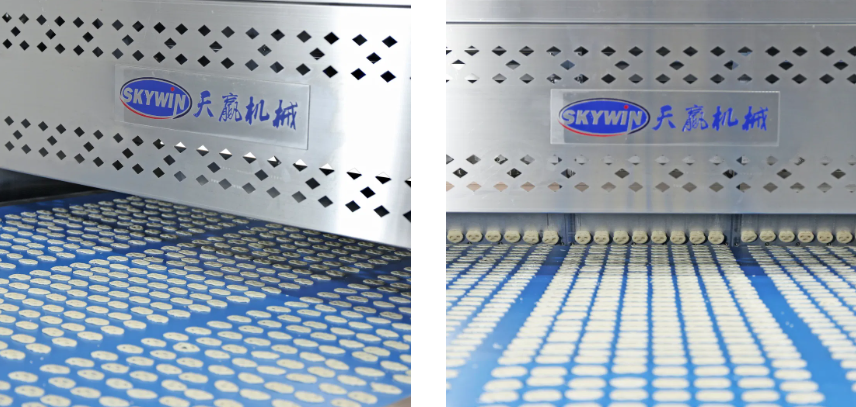

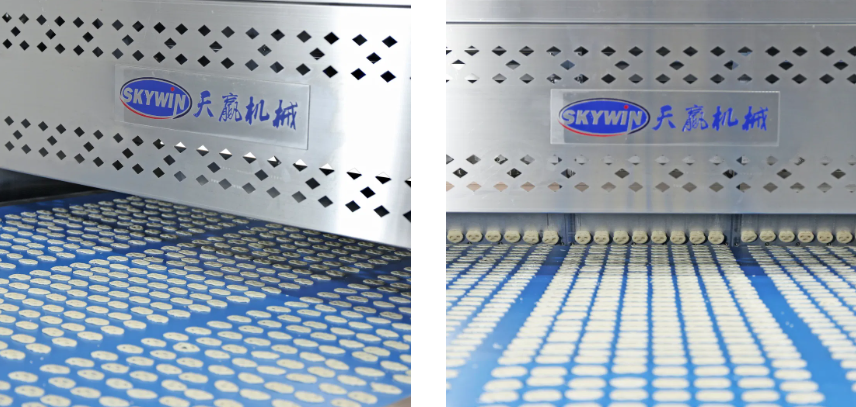

This item is a Fully Automatic Pretzel Biscuit Production line for stick biscuit, pretzel biscuit, pocky biscuit

Introduction:

1. Skywin Model 400mm or 800mm or 1200mm, capacity from 80kg-1800kg/hr.

2. To achieve an ideal effect, this Machine Biscuit can make various products' combination according to users' special

requirements, such as factory's layout and biscuit's style, shape.

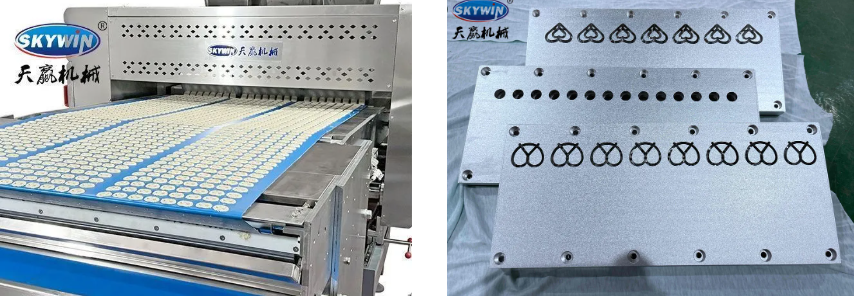

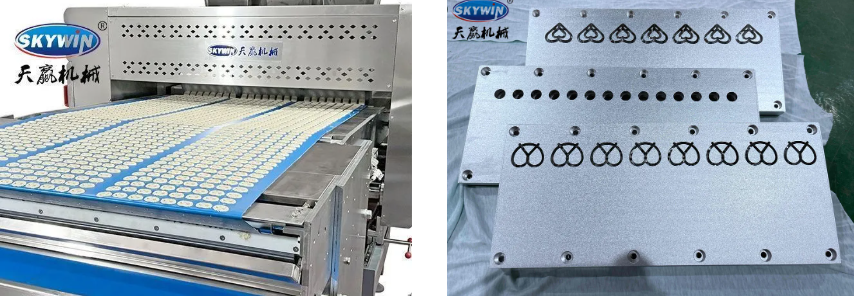

4. Different shape biscuit just need to change the mould, we also can design mould for you according to your requirement.

Machine component:1. Chinese famous brand motor & gearbox

2. Main bearing use Chinese brand, other small use NSK

3. AirTAC Pneumatic cylinder for belt tension and deflecting adjustment

4. PU and Cotton belt

5. 304 Stainless steel cover, thickness 1.5mm

6. SIEMENS transducer electric and PLC touch screen control.

7. Guarantee for 1 year along with recommended spare parts for 1 year.

A whole line consist of:1.Horizontal dough mixer

2.Automatic dough tipper and feeding system

3.Pretzel Extruder with Cutter

4.Pretzel Cooker

5.Salt and Sugar Sprinkle

6.Tunnel oven: Diesel, electric, indirect gas fried or hybrid gas oven for option

7.Turning machine 180° or 90° design as per the plant length

8.Cooling conveyor and stacking machine (start wheel stacker or penny stacker)

Key Features & Benefits:

High-Efficiency Production:

Scalable output from 80kg to 1,000kg/hr to match your production targets.

Precision Engineering:

304 stainless steel construction with rigid hopper ensures food-grade durability and hygiene.

Total Flexibility:

Produce unlimited biscuit styles (stick, pretzel, Pocky-style) via quick-change molds. Includes 3 standard molds + custom design service.

Smart Control:

Siemens transducer-driven PLC with touchscreen interface enables precise recipe management and real-time adjustments.

Automated Stability: AirTAC pneumatic cylinders maintain consistent belt tension and alignment – eliminating manual intervention.

Configured for You: Line layout and biscuit format (shape/style) optimized for your factory footprint and product range.

Reliability Commitment: 1-year full warranty + recommended spare parts kit for uninterrupted operation.

Parameter:

1. Scalable Production

Working Width: 400/800/1200mm (custom sizes available)

Oven Length: 20-60m (tailored to throughput needs)

Capacity:80-1000 kg/h (model-dependent)

2. Hygienic Construction

Full 304 stainless steel housing (1.5mm thickness)

Food-grade conveyor options: PU belt (oil resistance) / Cotton belt (high-temperature stability)

3. Intelligent Process Control

Siemens PLC with 10" touchscreen interface

Transducer-driven power management

4. Robust Drive System

Chinese Tier-1 motor & gearbox (industry-proven reliability)

Precision main bearings (Chinese premium brand) + critical auxiliary bearings (NSK Japan)

5. Application Versatility

Engineered for uniform baking of:

Stick biscuits | Pretzel twists | Pocky-style products

FAQ

Q1:Are you manufacturer/Factory?

A1:Yes,we are 15 years factory.

Q2: How long time to delivery?

A2: After received payment 30-50 working days.

Q3: How is the payment?

A3: We accept 40% T/T deposit before production and 60% T/T balance before shipment and Western Union or L/C.

Q4:What can you buy from us?

A4:Biscuit Production Line,Cookies Production Line,Biscuit Sandwich Machine,Wafer Biscuit Production Line,Biscuit Packing Line.

Skywin High Speed Pretzel Biscuit Making Machine Snack Production Line Bakery Equipment

This item is a Fully Automatic Pretzel Biscuit Production line for stick biscuit, pretzel biscuit, pocky biscuit

Introduction:

1. Skywin Model 400mm or 800mm or 1200mm, capacity from 80kg-1800kg/hr.

2. To achieve an ideal effect, this Machine Biscuit can make various products' combination according to users' special

requirements, such as factory's layout and biscuit's style, shape.

4. Different shape biscuit just need to change the mould, we also can design mould for you according to your requirement.

Machine component:1. Chinese famous brand motor & gearbox

2. Main bearing use Chinese brand, other small use NSK

3. AirTAC Pneumatic cylinder for belt tension and deflecting adjustment

4. PU and Cotton belt

5. 304 Stainless steel cover, thickness 1.5mm

6. SIEMENS transducer electric and PLC touch screen control.

7. Guarantee for 1 year along with recommended spare parts for 1 year.

A whole line consist of:1.Horizontal dough mixer

2.Automatic dough tipper and feeding system

3.Pretzel Extruder with Cutter

4.Pretzel Cooker

5.Salt and Sugar Sprinkle

6.Tunnel oven: Diesel, electric, indirect gas fried or hybrid gas oven for option

7.Turning machine 180° or 90° design as per the plant length

8.Cooling conveyor and stacking machine (start wheel stacker or penny stacker)

Key Features & Benefits:

High-Efficiency Production:

Scalable output from 80kg to 1,000kg/hr to match your production targets.

Precision Engineering:

304 stainless steel construction with rigid hopper ensures food-grade durability and hygiene.

Total Flexibility:

Produce unlimited biscuit styles (stick, pretzel, Pocky-style) via quick-change molds. Includes 3 standard molds + custom design service.

Smart Control:

Siemens transducer-driven PLC with touchscreen interface enables precise recipe management and real-time adjustments.

Automated Stability: AirTAC pneumatic cylinders maintain consistent belt tension and alignment – eliminating manual intervention.

Configured for You: Line layout and biscuit format (shape/style) optimized for your factory footprint and product range.

Reliability Commitment: 1-year full warranty + recommended spare parts kit for uninterrupted operation.

Parameter:

1. Scalable Production

Working Width: 400/800/1200mm (custom sizes available)

Oven Length: 20-60m (tailored to throughput needs)

Capacity:80-1000 kg/h (model-dependent)

2. Hygienic Construction

Full 304 stainless steel housing (1.5mm thickness)

Food-grade conveyor options: PU belt (oil resistance) / Cotton belt (high-temperature stability)

3. Intelligent Process Control

Siemens PLC with 10" touchscreen interface

Transducer-driven power management

4. Robust Drive System

Chinese Tier-1 motor & gearbox (industry-proven reliability)

Precision main bearings (Chinese premium brand) + critical auxiliary bearings (NSK Japan)

5. Application Versatility

Engineered for uniform baking of:

Stick biscuits | Pretzel twists | Pocky-style products

FAQ

Q1:Are you manufacturer/Factory?

A1:Yes,we are 15 years factory.

Q2: How long time to delivery?

A2: After received payment 30-50 working days.

Q3: How is the payment?

A3: We accept 40% T/T deposit before production and 60% T/T balance before shipment and Western Union or L/C.

Q4:What can you buy from us?

A4:Biscuit Production Line,Cookies Production Line,Biscuit Sandwich Machine,Wafer Biscuit Production Line,Biscuit Packing Line.